Chiller Tube Cleaning - An Overview

When was the last time any of us thought about the things we take for granted every day? Things like picking up the phone, getting a dial tone and placing a call, or turning the key in the ignition and having the car start. The fact is that we do not think of these things until they do not work right. The same holds true for air conditioning. We walk into a building on a hot summer day and take it for granted that we will be comfortable. We only think about the air conditioning system when it is not working.

It is the job of the HVAC maintenance technician to let us keep taking our comfort for granted. And it is no small task to accomplish this. For as sophisticated as today's chillers are with their electronic controls and microprocessors, it still takes a trained technician to see to it that all the bases are covered.

In large buildings, chillers are often the single largest consumers of energy. As energy prices increase, chillers can be identified as a potential source of significant energy savings. Preventive maintenance - everything from keeping a daily log to the weekly, monthly, and annual operational reviews, will yield optimum efficiency of the chillers. Read our blog for steps to improve your chiller maintenance.

Identifying Areas of Concern for Chiller Maintenance

Some of the major items of concern include the following:

Water Treatment

Some sort of water treatment is needed when condensers use an open cooling source, such as atmospheric cooling towers, to control scale, biological growth, and corrosion, which leads to fouling of the condenser. The more the condenser becomes fouled, the more energy the chiller consumes to satisfy the demand placed on it.

Refrigerant

It is important to maintain the proper refrigerant charge to minimize the load on the compressor and enhance efficiency. Refrigerant leaks decrease system efficiency, as do the introduction of air and moisture into the system.

Motors and Other Electrical Components

The chiller motor may be the largest single consumer of electricity in the building, so proper maintenance is important. It is important to make sure cooling air vents are kept clean on the motor and that shaft seals are checked periodically. Electrical connections, wiring, and insulation must be properly maintained for peak performance.

Lubrication

Compressor lubricant should be lab tested annually for moisture content, acids, and other contaminants that affect performance.

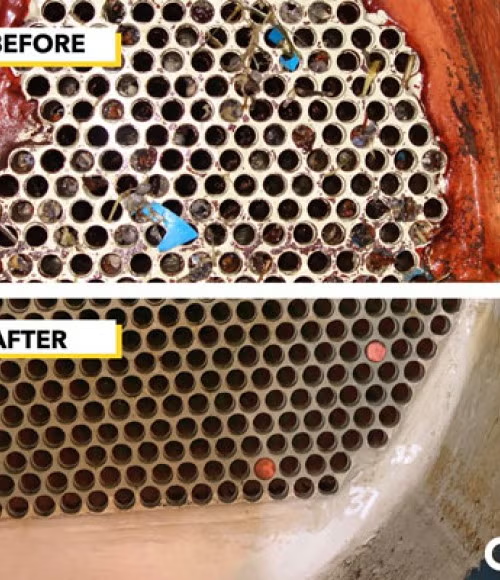

Condenser Tube Cleaning & Evaporator Tube Cleaning

Chiller efficiency is affected more by the cleanliness of heat transfer surfaces than any other single factor. Given that a chiller typically can have several miles of tubing making up the condenser and evaporator, it makes sense to keep chiller tubes as clean as possible by using a combination of water treatment and planned outages for tube cleaning and other major maintenance tasks.

As contaminants accumulate on chiller tube surfaces, efficiency declines rapidly. Contaminants can range from mud, sand, and algae to hard mineral scales, which increase thermal resistance and cause the chiller to work harder to meet demand, thereby consuming more energy.

How Fouling Factors Effect Chiller Performance % of Electrical Power Required

Fouling factor, loss of efficiency, and increased power needed.

- .0005 100% 0%

- .0015 94% 11%

- .0025 80% 22%

- .0036 58% 33%

- .0045 36% 44%

Tube Cleaning Methods

Many methods have been employed to clean chiller tubes, some with greater success than others. The following is a discussion of the various methods and their advantages and disadvantages.

Rod and Brush Method

Perhaps the rod and brush is the oldest and least pleasant chiller tube cleaning method. This involves using a length of rod, usually metal of some sort, with a nylon, or wire brush larger than the tube inside diameter, attached to one end. Typically, the tubes are flushed with water from a hose, then the brush is manually pushed through the tubes. The tubes are then flushed again with water.

Advantages:

- Low-cost

- Simple operation - requires little training or expertise

Disadvantages:

- Time and labor-intensive

- Because the brush bristles are folded over, they tend to swab the tube more than brush it

- Chiller tubes cleaned at the beginning of the job tend to dry with debris still in them, making the final water flush ineffective

- Requires enough space to utilize a rod slightly longer than the chiller tubes, to be cleaned (otherwise, rod sections must be coupled together further increasing the time needed to complete the job)

- Nobody wants to do the job, so it either does not get done, or it gets done poorly

Chemical Cleaning

Less prevalent now than in years past, this chiller tube cleaning method employs the use of acid solutions, which are circulated through the tube bundles, to break down, or soften scale deposits in the tubes.

Advantages:

- Under the right conditions, chiller tubes can be cleaned to bare metal

- Mineral scale can be softened enough to allow brush cleaning as a secondary operation

Disadvantages:

- Expense - chemicals can be costly and become an expense that is incurred every time tubes need cleaning

- Time-consuming - chillers are offline for at least 24 hours

- Chemicals are dangerous to work with,h increasing employee health and safety risks and employer liability

- With all the local, state, and federal restrictions on hazardous waste disposal, getting rid of used chemicals is difficult, costly, and carries some legal implications

- Requires significant training and expertise

Tube Cleaning Guns

This chiller tube cleaning method utilizes compressed air and water, or high-pressure water alone, to propel a cleaning projectile through the tubes to remove deposits. Projectiles can range from rubber bullets to brushes to plastic or metal scrapers of various kinds.

Advantages:

- Speed - tubes are cleaned in a matter of seconds

- Requires little training, or expertise

- Under the right conditions, tubes can be thoroughly cleaned with this method

Disadvantages:

- This method has limited capabilities in terms of the types of deposits it can remove (most projectiles are only suitable for light deposits, such as mud and algae)

- Both end bells must be removed to allow recovery of projectiles - which increases labor requirements

- High-water pressure units are costly and require considerable maintenance

- Safety - some guns are not vented to eliminate the possibility of "blowback" (This occurs when one attempts to shoot a projectile into a plugged tube. The tube becomes pressurized with air and when the gun is removed from the tube, the projectile is launched back at the operator.)

NOTE: Blowback only occurs with air/water guns that do not incorporate a pressure relief feature.

Online Systems

There are two basic online tube cleaning systems in use today. One utilizes plastic brushes, which are "trapped" using plastic baskets, that have been attached to each end of the tube using an epoxy. Periodically, the direction of the water flow through the tube bundle is reversed, causing the brush to travel to the other end of the tube. This back-and-forth brushing action is designed to keep the tubes clean. With the other type of system, a quantity of foam balls are loaded into the system to circulate through the system. In theory, a foam ball will travel through every tube in the bundle frequently enough to keep the tubes clean.

Advantages:

- Provided water treatment is right, these systems do work

- The maintenance personnel need not even think about tube cleaning

Disadvantages:

- Cost - systems necessitate a high initial outlay of capital to purchase and install

- They are not suitable where scaling commonly occurs (in areas where hard water is present, or where water treatment is poor)

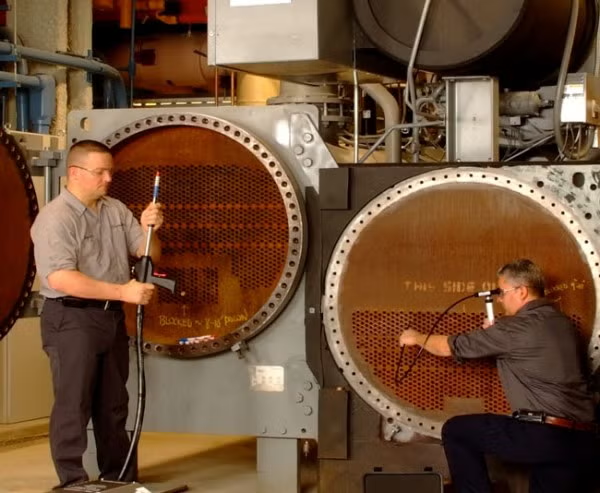

Rotary Tube Cleaners

These chiller tube cleaning devices utilize either an electric or air motor, to rotate a flexible shaft. It is encased in a plastic casing that transports water to the cleaning tool. Chiller tube cleaning tools range from a variety of brushes to buffing tools, hones, and scraper tools. They are capable of cleaning almost all types of deposits, including hard scale. The operator simply feeds the flexible shaft through the tubes to brush and flush in one operation.

Advantages:

- Affordable - initial outlay is minimal and the cost of consumables is reasonable

- Simple to use - little training, or expertise, is required

- Requires only one operator - reduces labor

- Chiller tubes are left thoroughly cleaned - better heat transfer

- Many models are available - from simple, no-frills machines to more advanced units, incorporating mechanical shaft feed, bi-directional rotation, and variable speed

- The most effective method for cleaning newer chillers that have internally enhanced tubes

- Only one end of the chiller tube needs to be opened for cleaning

Disadvantages:

- Slower than tube-cleaning guns

- Untrained operators may tend to break flexible shafts

Conclusion

Chiller maintenance is important for optimizing efficiency and extending equipment life. It takes training and knowledge to perform chiller maintenance properly. Isn't it interesting that the single biggest determinant of chiller efficiency is the cleanliness of heat transfer surfaces - primarily the tubes? The technologies discussed here enable maintenance personnel to get their tubes clean quickly and with minimal effort. Keep those tubes clean! It will save you money.

For more information on which Tube Cleaning method is best for your specific needs:

CHECK OUT OUR TUBE CLEANING BUYER'S GUIDE

For more information on what Chemical Descaling system and chemical are right for your specific needs: