The Dangers In Your Cooling Tower

What’s the Scoop on Viruses in Cooling Towers?

The current COVID19 pandemic has increased public visibility on infectious diseases throughout the world. Viruses like the novel coronavirus (aka COVID-19) that is currently impacting multiple nations worldwide comes with thousands of different characteristics that dictate their spread, survival rate, and degree of infection. With this particular virus, much is still unknown.

Numerous viruses throughout history have shown the capability to survive in the water in cooling towers if untreated. The main factors that influence a virus’s survival in water include temperature, organic material in the water, and the presence of aerobic microorganisms. Of these factors, the most critical influence on any virus’s survival is temperature. Every virus has its survivable range, but generally, a virus’s survival rate decreases with increasing temperature. High heat (above 100C) causes the fast inactivation of most viruses. The survival potential of a virus decreases even further with the presence of predatory microorganisms, such as protozoa which increase the inactivation rate of viruses in water.

Currently, it is thought that the novel coronavirus causing outbreaks of COVID19 worldwide is a not significant risk of contaminating industrial cooling towers. But little e research has been completed to date.

It may be worth noting, however, that when tested, the data has shown that most coronaviruses die off very rapidly in sewage wastewater, up to a 99.9% reduction of viral activity in water after two or three days of exposure. Viruses, however, adapt quickly to their environments as they spread across the world, and so facility managers need to continually update their maintenance plans to react to known global threats.

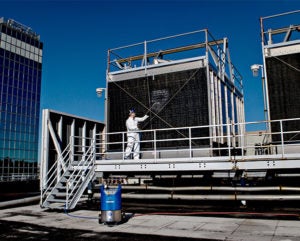

Protecting and Maintaining Cooling Towers

A building may not be occupied at the moment, but regular maintenance must remain essential. Facility managers have a significant responsibility to mitigate and prevent the contamination of cooling towers from diseases. Although not much is know yet on the current COVID-19 virus threat to cooling towers, bacterial contamination poses an even more severe risk to cooling tower maintenance, Legionnaires disease. Legionnaires disease is a notable bacterial infection that can thrive in aquatic systems such as cooling towers used in industrial cooling systems, evaporative coolers, nebulizers, and hot water systems. Similar to viruses, bacteria like the legionella pneumophila can infect the lungs of people inhabiting and visiting buildings and facilities.

A building may not be occupied at the moment, but regular maintenance must remain essential. Facility managers have a significant responsibility to mitigate and prevent the contamination of cooling towers from diseases. Although not much is know yet on the current COVID-19 virus threat to cooling towers, bacterial contamination poses an even more severe risk to cooling tower maintenance, Legionnaires disease. Legionnaires disease is a notable bacterial infection that can thrive in aquatic systems such as cooling towers used in industrial cooling systems, evaporative coolers, nebulizers, and hot water systems. Similar to viruses, bacteria like the legionella pneumophila can infect the lungs of people inhabiting and visiting buildings and facilities.

Cooling towers that supply water for central air-conditioning systems, in general, are a common culprit for outbreaks of disease. These cooling towers spread recycled and fresh air throughout the interior climate of a building. The best maintenance practices to prevent both viral and bacterial contamination inside cooling towers are aggressive cleaning plans paired with personnel training, monitoring, and testing.

The frequency and intensity of cooling tower cleaning should reflect the most recent government agency guidelines and the current local reports of contaminating risk levels. Frequent and lengthy scheduled cleaning of cooling towers will turn off critical building and operation equipment and will likely cause halts to facility operation. The risks to business operations need to be balanced with the current maintenance needs for facilities to ensure that business can continue while providing adequate maintenance for disease control.

Facility managers can take numerous steps to mitigate the effects that increased cleaning plans and equipment downtime have on facility operations. These steps include tiered maintenance plans, where the facility shuts down only portions of cooling towers and related equipment at a time to maintain some level of operation while maintenance is cycled. Facility managers can also invest in the effectiveness and speed of their cleaning equipment. Smart investments in cleaning equipment can decrease the total downtime of equipment during cleaning. Goodway has numerous cleaning and maintenance solutions that facility managers can implement to reduce cleaning times while increasing effectiveness. Goodway’s cleaning solutions provide an economical and proven solution to preventing viral and bacterial build-up in cooling towers.

The Dangers Of Ignoring Maintenance

Not correctly maintaining facility equipment, including cooling towers and water heating systems, can cost your thousands of dollars in repair and loss of efficient energy. But a danger much greater can be the fallout of a Legionella breakout. Take the mishandling of a Legionella breakout at an Illinois Veterans Home. After a year-long investigation of the break out that killed more than a dozen residents, Illinois paid nearly $6.4 Million to the families of the Veterans who lost their life to Legionella. General Frank Maution’s audit revealed the discharge of gallons of stagnant water when a hot-water heat was improperly returned to service that was previously offline. The leap that can be taken from a poorly maintained water tank to a cooling tower is not far apart. When water is left stagnant, a breeding ground for bacteria is created. Many buildings are unoccupied with non-essentials workers at home but make no mistake that regular maintenance is essential to keep buildings healthy for the return of occupancy.

Next Steps:

Research the complete line of Goodway’s Cooling Tower Cleaning Solutions to find the right solution for you.

Watch our webinar Preventative Maintenance for Cooling Tower Systems

Check out our 9 Tips To Controlling Legionella in Your Cooling Towers