Discover the Right HEPA Filter Vacuum For You

We offer a variety of HEPA industrial vacuum cleaners at Goodway Technologies. You can choose from various configurations to meet virtually any cleaning need. These systems provide incredible filtration performance. Suitable for cleaning sensitive areas, lead dust particles, silica dust, lithium, and more.

Use this guide to determine if a HEPA filter vacuum is right for you.

DID YOU KNOW?

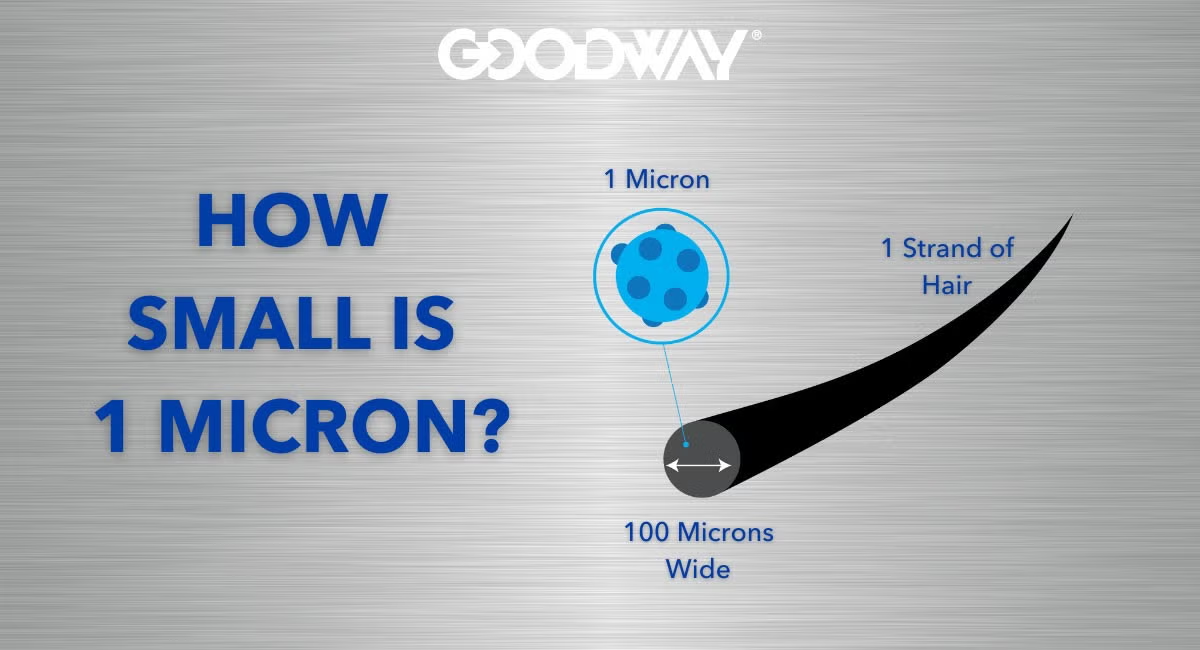

To give you an idea of how small a micron is, consider that human hair is about 100 microns wide. A tobacco smoke particle is usually between .01 to 1 micron, and most bacteria particles fall in the .35 to 10-micron range.

Any particles smaller than 10 microns are invisible to the human eye. So a particle of only .3 microns is tiny, and HEPA filters can capture many particulates of that size.

What is a HEPA Filter Vacuum?

Goodway offers a wide selection of Industrial HEPA Vacuum Cleaners. HEPA industrial vacuum systems offer incredible filtration performance and can be configured to meet any cleaning requirement. These HEPA filter vacuums are perfect for cleaning sensitive areas where small particle filtering is required. Examples include lead dust particles, silica dust cleanup, allergens, fine specks of dust, and more.

Why are HEPA Filters Important?

The quality of HEPA filters matters. There are several reasons why HEPA filters are used, including preventing allergy-causing particles and bacteria, controlling allergens in hospitals and laboratories, and even accommodating bioterrorism agents in industrial plants. HEPA vacuum cleaners effectively improve indoor air quality by removing debris and reducing harmful contaminants. When maintaining a high indoor air quality (IAQ) standard is paramount, HEPA filters are most often recommended. Indoor air quality is increasingly prioritized in commercial buildings because poor air quality negatively impacts allergy sufferers, asthmatics, and other respiratory patients.

Most of the time, vacuum cleaners collect dust, dander, and pollen from surfaces, but they also add more small particles to the air, which people are exposed to. HEPA vacuum cleaners capture these tiny particles that get kicked back into the air to keep the air clean.

DID YOU KNOW?

High-Efficiency Particulate Air (HEPA) filters have evolved from equipment with specialized uses to a product used in hundreds of applications worldwide in the past 50 years. It originally was used in the Manhattan Project to clean the air in cleanrooms where the world's first atomic bomb was made, but it now is used for items as diverse as asbestos abatement and lead-based paint removal to general cleanup and even home-owner use.

Where to Use HEPA Filters Vacuums:

- Industrial applications

- Silica removal

- Lithium pickup

- Hospital cleanup

- Laboratories

- Asbestos removal

- Sensitive IAQ environments

- and much more

DID YOU KNOW?

HEPA filters are made up of a mat-like material with fibers. The fibers must be arranged precisely so that particles stick to the fibers in one of three ways, according to IAQSource.com:

1. Interception: this is the first line of defense, where most particles in the airflow stream naturally adhere to the fibers.

2. Impaction: this is the second line of defense, where the particles that are too large for interception are trapped in the curved contours of the fibers.

3. Diffusion: this is the final defense, which traps molecules that are too small for either interception or impaction by forcing them to collide with gas molecules.

True HEPA vs. HEPA Type and Why It Matters

The Underwriters Laboratories safety standard is a benchmark for HEPA filter performance. When a HEPA Filter passes the UL test, an air purifier or filtration system can be granted its mark (typically letters “UL” in a circle).

True HEPA: To be deemed a True HEPA filter, the filters must remove 99.97 percent of all particles of 0.3 microns in size. There is no label with any real meaning other than True HEPA (or sometimes Absolute HEPA), as it is the only one that claims to adhere to a standard. Goodway HEPA Filter Vacuums have been tested and certified.

HEPA Type/Like: A HEPA Type/Like Filter is meaningless because it does not comply with any standard. Since it has not been tested, it will not perform nearly as well as a HEPA filter or be ineffective.

How To Choose the Right HEPA Filter Vacuum?

To start, you need to identify when to use a HEPA filter Vacuum:

- Lead paint – To comply with EPA rules when working with lead paint, you must use a HEPA vacuum to clean any walls or other surfaces covered in dust.

- Asbestos – To prevent fine particles or powder from escaping into the atmosphere and posing possible health hazards, any material that contains or might contain asbestos must be cleaned with a HEPA-filtered vacuum system before a renovation, repair, or replacement.

- Clean environments – An environment where immaculate, dust-free conditions are necessary, such as one where delicate electronic gear or optical/photo equipment is present. Another excellent place for HEPA vacuums is on the production floor of a food or pharmaceutical company.

- Biological contamination – Since HEPA vacuums capture so much dust, they could be the best cleaning solution after a vermin, bird, or creature infestation. A HEPA vacuum is also standard to remove any mold or mildew.

- Nuclear Power – Places where radioactive materials must be cleaned up, such as power plants, laboratories, and hospitals, are perfect for HEPA vacuum cleaners.

Next, you need to identify the types of HEPA filter Vacuums available:

- Industrial

- Portable

- Wet/Dry

- Wall Mounted

- Continuous Duty

- HEPA with Hazardous Material

- Attachable Accessories

DID YOU KNOW?

As the last filtration step, a HEPA vacuum cleaner uses a high-efficiency particulate air (HEPA) filter. HEPA filters can capture particles as small as 0.3 microns with a 99.97% efficiency rate. A micron, or "micrometer," is equal to 0.00004 inches.