Simple Steps To Clean Cooling Tower Scale From Tower Fill

Scalebreak® quickly removes deposits like lime, scale, and rust that otherwise drastically reduce efficiency, increase expenses, and damage to vital components.

Our seventh and final installment in our series, Cleaning with ScaleBreak®, focuses on cleaning cooling towers with Scalebreak Gel.

Goodway’s ScaleBreak Gel is a patented, innovative viscous gel formulated for descaling vertical surfaces like cooling tower fill. When cleaning the fill on a cooling tower, you will first need to visit our calculation tool at www.goodway.com/resources/calculators#!/scalebreak-gel, so you know the proper amount of ScaleBreak Gel needed. The information in the calculation tool allows you to adjust the amount of Gel based on the thickness of scale you need to remove from your tower fill. ScaleBreak Gel is designed to be used in conjunction with our TFC-200 application unit.

- Turn off all water treatment chemicals, pH & conductivity meters. It is equally important also to shut off or disconnect any non-chemical systems, especially alternating high-frequency electric types, as leaving this technology on may cause unintended damage during the cleaning process.

- The fan must be turned off during the Gel application. This will allow the Gel to remain in the applied areas.

- Once the tower is shut down, please be sure a few inches of water is in the basin.

- In the back of the TFC-200 is a hook-up for your 5-gallon pail of Gel. Remove the cap on the Gel container, raise the dip tube, and place the pail in the TFC-200. Then lower the dip tube into the Gel and lock it into place using the cam lock collar. Strap in the 5-gallon pail, so it is secure.

- When assembling your application wand, be sure to utilize the 45° angle as this will allow you to spray the fill at the proper angle and put the yellow nozzle on. The yellow nozzle is for water and will saturate the fill faster.

- Connect a water supply to the “water inlet” garden hose fitting on the back of the TFC-200.

- Plug in your TFC-200 to any 110-volt outlet, the power light on the front panel should be illuminated. If the light does not come on, depress the reset button on the GFCI.

- Your TFC-200 has 2 pumps, one is for applying the viscous Gel product, and the other is a low pressure/high flow pump for flushing off the Gel and debris.

- On the top panel of the TFC-200 is a black toggle switch. Flip it down to the rinse/mix position.

- On the top panel is a yellow handle; this should be moved, so it is pointing straight down to a 6 o’clock position “rinse.”

- You want to first liberally rinse down the fill and flush off any loose debris.

- The fill where you are going to apply the Gel should all be thoroughly wetted.

- Change your sprayer to the white nozzle; this nozzle is for applying the Gel.

- Move the yellow handle to the left, so it is pointing at the 9 o’clock position “chemical.” This will switch your TFC-200 over to the mode where it will begin to apply the Gel. Please note: the Gel should be applied neat and not diluted with water.

- On the control panel, flip the toggle switch to the up position “chemical.”

- Important: ScaleBreak Gel should only be applied straight; if you dilute it with water, it will lose its ability to cling to the fill.

- Each 5-gallon pail of Gel will clean approximately 100 square feet of fill material. Tower fill with thick deposits will require additional Gel.

- Liberally apply Gel to all the surfaces on the fill sheet. If any of the Gel gets on the metal surfaces, it should be rinsed off. ScaleBreak Gel should only be used on the plastic fill material.

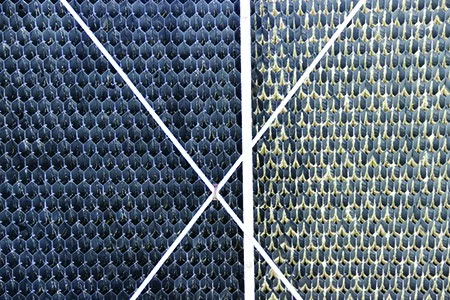

- Allow the Gel a minimum of 60 minutes of contact time on the fill. This time duration will allow the Gel to penetrate the deposits and loosen their bond. If the deposit is calcium carbonate, the Gel will begin dissolving it, and you will see an effervescing reaction.

- Once the Gel has been applied to one side, you can move around to the other side of the tower and apply the Gel on that side. Please remember the Gel needs 60 minutes to perform its task.

- Once the Gel has reached the 60 minute time duration, you can begin to flush off any remaining Gel, loose debris, and deposits.

- On the top of the TFC-200, move the yellow handle straight down to the 6 o’clock position “rinse.”

- On the top control panel, move the black toggle switch to “rinse/max.”

- Attach the black turbo nozzle.

- With your Turbo nozzle, begin to rinse away the deposits and or debris. Again, please keep the tip of the nozzle 18” from the fill sheet surface.

- If the deposits were thick, you might have to re-apply the Gel until completely clean. Follow steps 13-18 for any re-applications of Gel.

- Once you have determined all the fill areas are clean and no additional Gel or debris remains, you can begin the clean-up process.

- Test the pH of the water in your sump basin to make sure it meets release limits. If the pH is low, you can add ScaleBreak Neutralizer until the pH reaches the proper release value.

- After the cleaning, some of the debris may now be in the bottom of the basin; you can utilize our Cooling Tower Vacuum (CTV) to vacuum this debris out.

- Once the tower basin has been flushed and cleaned of any remaining Gel and particulate, you can reestablish pH & conductivity meters, turn on non-chemical treatment systems or water treatment chemical feeds.

TFC-200 cleaning procedure

- Raise the dip tube for the removal of the chemical container.

- Screw the cap back onto the chemical container for transport.

- Unstrap the chemical container and remove it from the TFC-200.

- Place a bucket of clean water into the rear container storage area.

- Lower the dip tube into the bucket of clean water.

- Turn the valve on the front panel all the way to "chemical."

- Point the spray gun in a safe direction and squeeze the trigger.

- After 3-5 minutes, turn the pump off and then release the spray gun trigger.

- Raise the dip tube and remove the bucket with the remaining water.

- Your TFC-200 has been properly rinsed and will be ready for the next usage.

Please note:

- Wear safety glasses with non-perforated side shields when applying ScaleBreak Gel.

- It is recommended that gloves be worn during use with ScaleBreak Gel.

- Follow all plant personal protective equipment guidelines and consult with your health & safety team.

- Follow all local regulations for discharge.

Please contact Goodway Technologies with any questions.