How Clean-in-Place Conveyor Belt Cleaning Delivers Efficiency, Labor Savings and FSMA Compliance

When it comes to investing in conveyor belt cleaning equipment, many factors come into play. Return on investment is influenced by production uptime, savings in staff time, and meeting regulatory requirements. Keep in mind new FDA regulations tighten up existing rules by focusing on preventing contamination, rather than limiting their scope.

When it comes to investing in conveyor belt cleaning equipment, many factors come into play. Return on investment is influenced by production uptime, savings in staff time, and meeting regulatory requirements. Keep in mind new FDA regulations tighten up existing rules by focusing on preventing contamination, rather than limiting their scope.

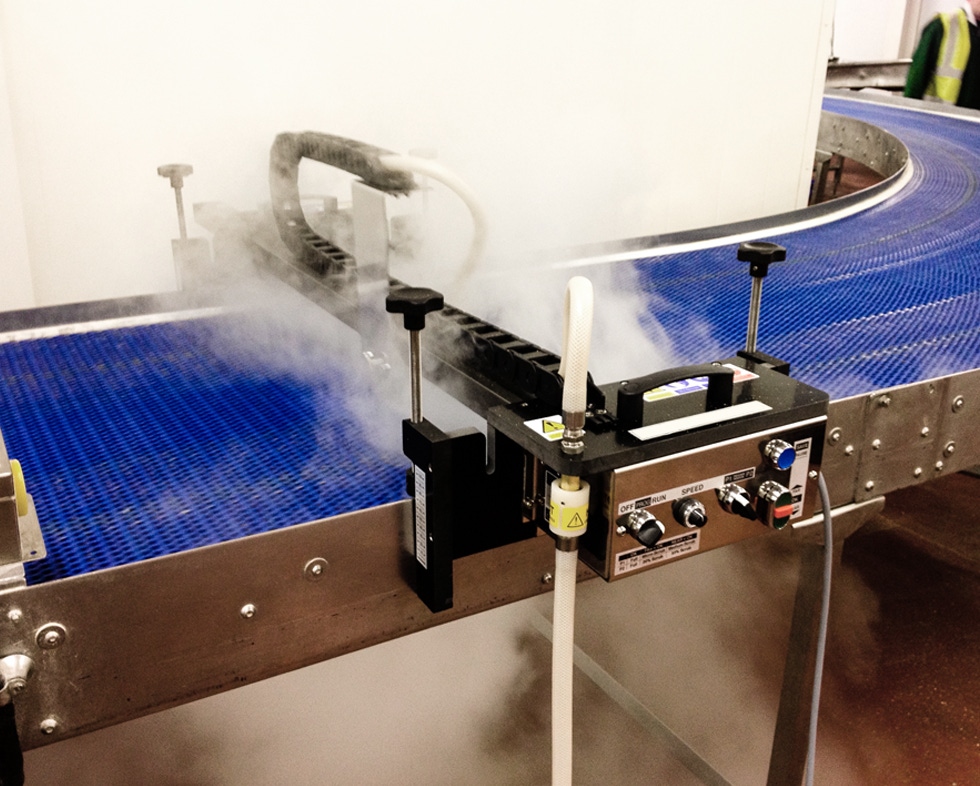

Dry vapor steam technology, however, is a clean-in-place solution that is faster, more effective, and safer. You can accomplish in a couple of hours what might have taken a full shift or even days to do previously. This means the plant is kept up and running, doing what it’s supposed to be doing — producing food, beverage, or other products. What’s more, dry vapor steam provides a more thorough clean than even the best human hands ever could. Contact surfaces will be more hygienic and it’s a safer alternative to harsh chemical cleaners.

So take a brief look at why dry vapor steam conveyor belt cleaners are the growing choice in the food and beverage industry. In its most basic form a steam cleaner is a heater that brings water up to approximately 290°F then releases it at about 145 PSI of pressure through a small nozzle. The water then goes through a flash stage where it gains velocity as 90% or more of it turns to steam. These fine water particles are still superheated when they come in contact with a greasy or dirty belt. The combination of heat and force lifts the grime from the belt, instantly kills bacteria, and dries virtually instantly.

Dry vapor steam cleaners remove more of the grease and allergens, leaving significantly less water behind than a wet steam solution, high-pressure water, or using a more manual process. They also require fewer chemicals and provide the added benefit of sanitizing. All this is achieved while avoiding belt damage, which reduces the risk of foreign object contamination, enabling regulatory compliance.

Consistently removing contaminants and leaving less water around improves equipment reliability, and avoids mold and bacterial growth. Continuous in-place cleaning means no downtime and no staff time. Using fewer chemicals reduces food contamination risks. Providing a high-quality and sanitized clean enables hygienic and safe production lines.

Because heating the water and in-place cleaning do not require any moving parts, maintenance costs for quality equipment remain low and the initial outlay is comparable to the risky and wet, high-pressure cleaners. In combination, this makes industrial steam cleaners the preferred belt cleaning solution.

Next Steps:

- Watch our podcast on how food production facilities can prepare for FSMA

- Subscribe to our blog to receive the full blog series via email and stay informed about the latest HVAC news and insight.

- Get help in choosing the right products for your needs by browsing these buying guides: Industrial Vacuum Cleaners, Coil Cleaners, Chiller Tube Cleaners, Cooling Tower Cleaners, Industrial Pressure Washers