Latest Cooling Tower Legionella Outbreak Underscores Cleaning Solution Challenges and Importance of Ongoing Maintenance

Another Legionella outbreak linked to cooling towers this week re-emphasizes the urgent need for facility managers to develop an effective cooling tower maintenance program. As we mentioned in part one of this two-part blog series on cooling tower cleaning solutions, various studies strongly suggest 40% to 60% of cooling towers test positive for legionella.

Another Legionella outbreak linked to cooling towers this week re-emphasizes the urgent need for facility managers to develop an effective cooling tower maintenance program. As we mentioned in part one of this two-part blog series on cooling tower cleaning solutions, various studies strongly suggest 40% to 60% of cooling towers test positive for legionella.

This latest outbreak of the potentially deadly disease was caused by poorly maintained cooling towers in buildings around the central business district in Melbourne, Australia.

Five people between the ages of 51 and 71 were hospitalized. Authorities in Melbourne are analyzing 92 building systems in an attempt to lock down the source of the outbreak. While all five people have been discharged and are recovering, one had been on life support in intensive care.

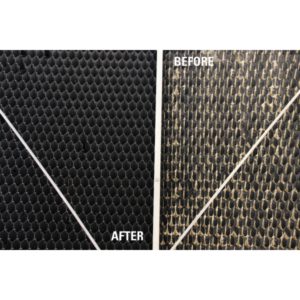

Cooling towers with heavy limescale buildup on their cooling tower fill can be the perfect breeding grounds for legionella. Once the bacteria gains a foothold, it can infect the entire system. That means sick buildings and sick people, or worse. Short of sickness, dirty cooling towers can make your building smell bad, driving customers away. And there’s also the cost to your company’s image, which might never recover.

Limescale buildup in cooling tower fill isn’t just unsightly, unpleasant and dangerous. Dirty cooling towers increase costs, big time. Limescale buildup can dramatically decrease cooling tower efficiency. That’s potentially thousands of dollars added to your electricity bill for significantly reduced performance.

Still, cleaning dirty fill is a giant headache. It’s filthy, labor-intensive work, especially when done the old fashioned way, scraping limescale off by hand. Cleaning a heavily scaled up cooling tower usually requires multiple tools. Changing tools adds more time to an already labor-intensive process. No wonder so many businesses put off cleaning cooling towers.

However, there is an all-in-one solution available to help you keep your cooling towers clean that’s simple to operate. First, rinse down the cooling tower using an integrated power washing function. Then use an integrated chemical applicator to apply a powerful, yet safe, chemical descaler gel. The gel immediately reacts with limescale deposits to help dissolve and remove them, on contact. The final step is using an integrated turbo nozzle that includes a unique spray pattern to power clean the deposits. If limescale isn’t the issue with your cooling tower fill, use a foaming cooling tower fill cleaner and turbo nozzle combination to remove biological matter and dirt.

Check out this video to get a better sense of the simplicity and effectiveness.

An all-in-one solution means fewer man hours spent cleaning cooling towers and less downtime. That means you won’t have to put off cooling tower cleaning until the last minute, saving your company tens of thousands of dollars in reduced electricity costs annually — and no bad publicity for being the source of the latest outbreak of Legionnaires’ disease.